How many parts of the crane do you know, and what are they?

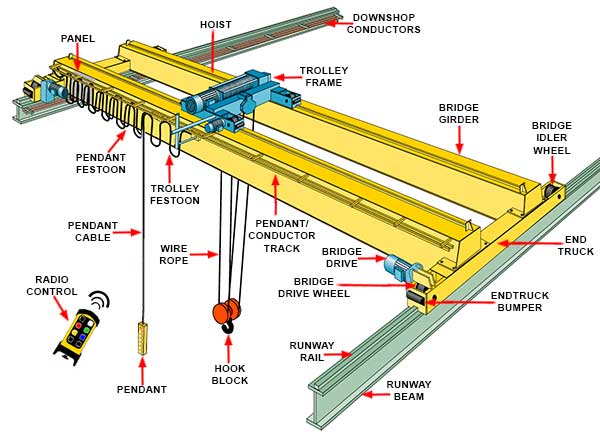

Crane provides great convenience for various industrial production, so parts of the crane have a directly impact on crane operation and efficiency. For bridge crane, main parts of the crane are electric hoist, trolley, bridge girder, and end truck, etc. For jib crane, parts of the crane also involve jib, column, and rotary switch, etc. The following article mainly introduces parts of the bridge crane.

End truck

End truck plays an important role in the parts of crane, it is the key part of lifting for both underhung and top running bridge crane. The end truck is composed of wheel group and end truck frame, the main parts of end truck is composed of upper and lower cover plate and two pieces of web. The end truck is composed of two segments connected with the angle steel by high strength bolts. The interior of the end truck is provided with a reinforcing bar to ensure the stability of the end truck. The main size of end truck is determined according to the span of bridge girder, wheel distance and trolley span. During the crane is assembled, a section of the end truck is connected with one of the bridge girders, and then the two section of the end truck is connected.

Bridge girder

Bridge girder of a crane is used for carrying heavy loads. The main differences between bridge girder and end truck are that there are wheels installed on end trucks, but bridge girder without. The main function of bridge girder is used to hang hoist and provide space for the trolley operation. Steel used for bridge girder production is generally Q235, if the crane needs to work below minus 20℃, then select 65Mn.

Electric hoist

Electric hoist, which is installed on the crane, is a kind of special lifting equipment that can operate up and down, or left and right, but can’t move back and forth. With advantages of small size, light weight, simple operation, and easy to use, it is widely used in a variety fields, including the industrial, mining, terminal, etc. The most common used electric hoists in today world are two types, wire rope electric hoists and chain electric hoist.Wire rope hoists

Wire rope electric hoist is small lifting equipment, this kind of electric hoist has the advantages of compact structure, light weight, small size, strong commonality, and easy operation. Wire rope hoists can be installed either on the I – steel, or on the electric or manual crane, from singe girder to double girder, from jib crane to gantry crane. It will take only a few minutes to complete the wire rope, also with the advantages of large pulling force and nicer appearance for a pressed wire rope, the wire rope hoists greatly reduces the labor intensity, and improves the work efficiency.Wire rope electric hoist tonnage is 0.5T/1T/2T/3T/5T/10T/16T/20T, standard meters of wire rope are 6M/9M/12M/18M/24M/30M. It is also divided into single speed type and double speed type.

Wire rope hoists application

Wire rope electric hoists are mainly used in all kinds of lifting, pulling, loading and unloading heavy, oil tank flip welding, such as large and medium concrete, steel structure and mechanical equipment installation and mobile, they apply to construction and installation companies, factories and mines of civil engineering and bridge construction, electric power, shipbuilding, automobile manufacturing, buildings, roads, bridges, metallurgy, mine, slope tunnel, well management and protection of infrastructure projects machinery and equipment.Structure features of wire rope hoists

Wire rope hoists are consist of motor, drive mechanism, drum, and wire rope. It can be divided into four types according to the position of motor and drum:- Electric hoist, whose axis is perpendicular to the axis of the drum, is driven by a warm gear. But this kind of electric hoist is difficult to produce, because of the large size and bulky structure. So there is no one has used this kind of electric hoist now.

- Electric hoist, whose axis is paralleled to the axis of the drum, has advantages of small length and height. But its disadvantages are that the weight is large, the production and installation are difficult, and the rail turning radius is large.

- Electric hoist, whose motor is mounted in the drum, has advantages of small length and compact structure. The main disadvantages are that the motor heat dissipation condition and grouping are poor, the power supply device is complex, and it is inconvenient to inspect, install, and maintain the motor.

- Electric hoist, whose motor is mounted outside the drum, has advantages of well grouping, high generalization, easy to change the lifting height, and convenient to install and inspect. The disadvantage is that the motor length is large.

Chain hoist

Chain electric hoist makes up the disadvantages of large and bulky volume of wire rope electric hoist. Chain electric hoist is composed of electric motor, drive mechanism and chain wheel, and the biggest difference compared with wire rope hoist is that it changes the wire rope into chain. The lifting weight is generally 0.5 ~ 60 tons, and lifting height is generally 3 ~ 120 meters.

Chain hoist features

Chain electric hoist retains the characteristics of light and convenient for manual hoist, and improves the disadvantages of manual hoist like manual control and the lifting speed is slow, the advantages of manual hoist and electric hoist are gathered. Chain electric hoist adopts disc brake motor as the pin reducer to reduce the speed. It has various advantages like compact structure, light weight, high efficiency, reliable, and easy to operate and maintain. Chain hoist contributes great convenience to variety fields for cargo handling. It can also be installed on the suspended I – beam, orbit curve, jib crane rail and fixed point to heavy weights.Chain hoist application

The chain electric hoists are widely used in ports, power, steel, shipbuilding, petrochemical, mining, railway, building, metallurgy chemical industry, automobile manufacturing, plastic machinery, industrial control, highway, bulk transportation, pipeline auxiliary equipment, side slope tunnel, well road management and protection, marine salvage, ocean engineering, airport construction, bridge, aviation, aerospace, venues and other important industries, as well as a variety of basic construction projects required for machinery and equipment.Trolley

A trolley, which is equipped with main hook and secondary hook, is installed on the bridge girder of crane. Unlike electric hoist can operate up and down, or back and forth, the trolley can just make a longitudinal operation along the bridge girder in order to adapt to the lifting position.The trolley is composed of a lifting mechanism, a trolley running mechanism, and the trolley frame. The lifting mechanism is made up of motor, brake, reducer, drum and wheel. The motor drives the reducer to rotate through the drum, in order to make the wire rope wound on a reel or put down from the reel, to lift weight loads.